The Quality Improvement Summit under the New Development Pattern, jointly organized by the Guangdong Provincial Quality Development Promotion Association and the Shenzhen Quality Innovation Technology Alliance, was recently held in Guangzhou. SiE Information was invited to participate in this grand event and shared the path of comprehensive quality management and operation in the digital era with on-site experts, scholars, guests, and enterprise representatives. At the roundtable meeting, discussions and exchanges were held with representatives from various industries and government experts.

In the digital age, the "digitalization" upgrade of enterprise quality has become a trend

In the domestic cycle, consumption is the main support for expanding domestic demand and also an important driving force for production. With the improvement of China's national living standards, quality consumption and brand consumption have become the trend of modern consumption methods. Therefore, enterprises need to strive to improve the quality of products and services to meet the consumer pursuit of the people.

In the quality development of enterprise products and services, quality efficiency is the biggest weakness and bottleneck. How to utilize digital and intelligent information processing to improve the quality and efficiency of enterprises and help them carry out comprehensive quality management operations? At the meeting, SiE Information brought SiE SQMS (Quality Management System) solution sharing.

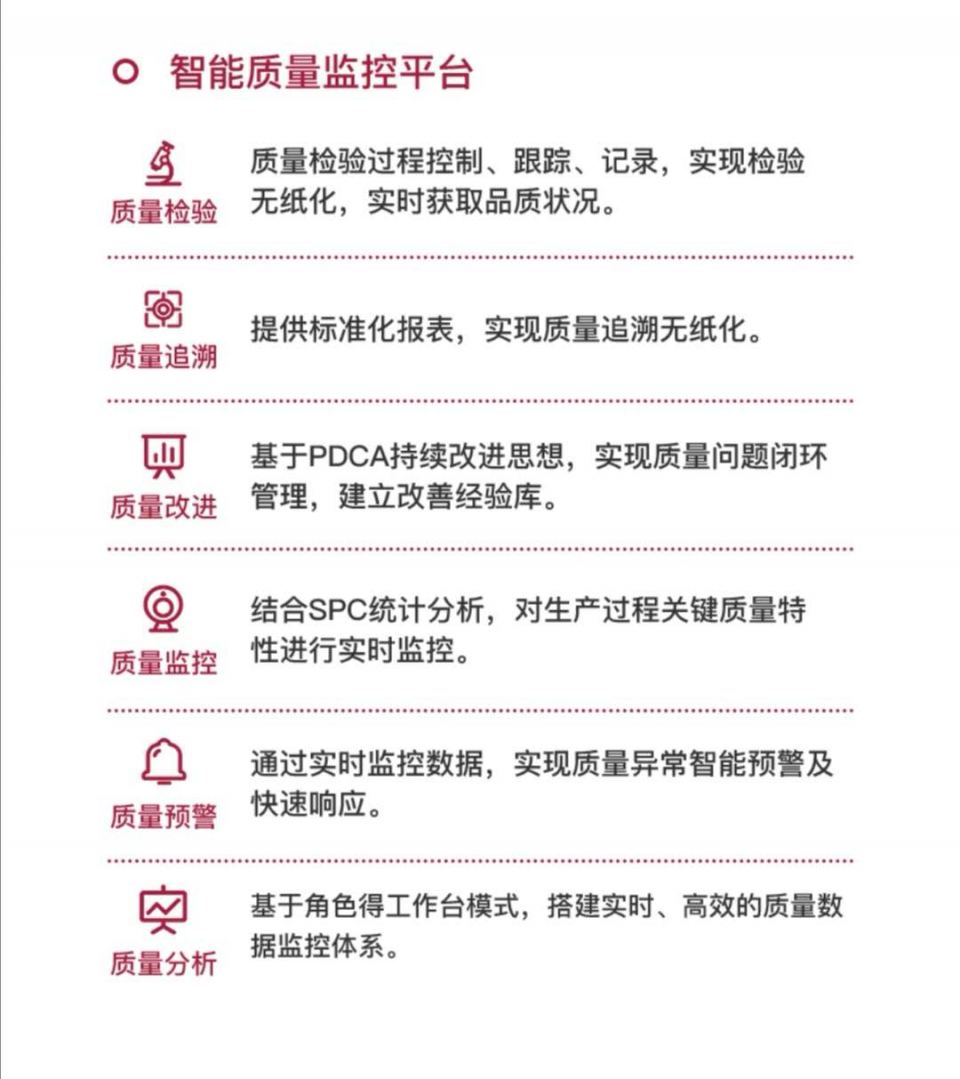

SiE Information SQMS system integrates the practices and summaries of various industries, especially in discrete manufacturing customers, and is committed to establishing a quality management system of "PDCA continuous improvement" to achieve quality monitoring, early warning, analysis, and improvement of the manufacturing process. The core modules of the product include: inspection standard management, incoming material quality management, process quality management, finished product quality management, PDCA quality improvement management, SPC monitoring and early warning. Through each module, supplier quality control, production process quality control, quality analysis, real-time dashboard monitoring, etc. are achieved.

The Five Advantages of SiE Information SQMS Help Enterprises' Quality Digitalization "Advance"

In the new era of digitalization, data will become an important productivity for enterprises. By utilizing the SiE SQMS system for digital construction, we aim to reduce inefficient and repetitive work with high error rates, reduce unstable factors in human operations, and release labor, thereby improving the quality and efficiency of enterprise production and reducing enterprise costs.

1. Efficient execution: real-time task push to improve inspection efficiency

Based on the concept of "convenience, speed, and efficiency", achieve efficient execution. SPC management tools can flexibly interface with various on-site testing equipment, achieving real-time monitoring and early warning of production process abnormalities. In addition, flexible sampling schemes and intelligent sampling transfer rule algorithms can be configured to achieve fast and efficient task execution.

2. Convenient management: real-time data analysis, visual management

Based on workbench management ideas, achieve convenient management. By implementing process visualization and intelligent analysis, we can grasp the overall trend of quality changes and make decisions more accurate. In addition, in terms of technical security, it supports RBAC security authentication and hierarchical permission control.

3. Quick response: Real time monitoring, timely feedback on quality abnormalities

Based on the application of "SPC statistical analysis", advanced IT information technology and traditional statistical theory are utilized to achieve real-time monitoring, warning, and improvement of quality information collection and statistical analysis throughout the entire process.

4. Continuous improvement: closed-loop quality issues, sharing of improvement experience

Based on the concept of "PDCA management", analyze, improve, track, and verify abnormal problems discovered during the production process, accumulate improvement experience, and continuously improve product quality.

5. Mobile office: instant response to tasks, timely on-site collection

Based on the demand of "real-time, intuitive, and convenient", mobile office is achieved. Supports B/S and C/S technology architectures, with multiple user experience modes on PC and mobile platforms. In addition, it can also achieve task push by responsibility, automatic sorting of emergency documents, and recording upon inspection, improving data authenticity.

Let quality speak up ", a one-stop visual quality monitoring platform

During the round table session of the event, SiE Information and representatives of various enterprises and government experts expressed their opinions on the issues of quality improvement paths and brand building.

Wang Weize, General Manager of SiE Information Market, stated that in order to improve the quality of products and services and brand building, the key is for enterprises to make quality speak up. Through digital technology, the data in the production process, including traceability of raw materials and production processes, can be presented to consumers in a visual and digital form. Only by sincerely facing consumers and daring to showcase the production process to them can enterprises improve product quality under their supervision. At the same time, consumers' supervision and perception of product use will also feed back to enterprises, improving their service quality.

The SiE Information SQMS quality management system assists enterprises in achieving data standardization and integration through the entire quality process of prevention, control, analysis, improvement, and traceability; Visualization of quality management, real-time warning, and improved closed-loop tracking; Comprehensively improve the quality assurance capability of enterprise products, and establish a one-stop quality monitoring platform based on PDCA closed-loop management as the core idea.

This year, the COVID-19 has swept the world. Under the background of complex international environment, the improvement of enterprise quality and overall operation is also the key to enhance enterprise competitiveness. Enterprises are accelerating the implementation of the three modernizations of quality: data-driven, online, and transparent. Through professional and reliable digital technology service providers, the production data of enterprises can be collected and analyzed according to established plans, and monitored online in real-time in the quality system, in order to timely discover and solve problems. While improving the quality of enterprise production, consumers can perceive the positive development of the digital quality system in the enterprise, and the production quality situation is transparent and open to the public, so that consumers can use products with peace of mind, Establish a good and trustworthy consumption environment.

As a manufacturer of SMOM-QMS products, SiE Information continuously listens to customers' production needs and accelerates the pace of product upgrade iterations. The SQMS quality management system has been upgraded and iterated to version 8.2, which is more in line with the more precise quality management requirements of enterprise users. At present, SiE Information SQMS has served dozens of globally renowned enterprises such as TCL, vivo smartphones, Panasonic Appliances, and Sofia Furniture.