Made in China 2025 focuses on intelligent manufacturing, with power equipment being one of the top ten key areas. From September 23rd to 25th, the Small and Medium Motors Branch of the China Electrical Appliances Industry Association and Shanghai Motor System Energy Saving Engineering Technology Research Center Co., Ltd. hosted the 2020 Advanced Technology Training Course for Intelligent Manufacturing Digital Workshop Construction in the Motor Industry (Phase 2). SiE Information was invited to the venue to share the theme of "Exploration and Practice of Digital Factory 2.0".

Digital factory refers to a new production organization method that simulates, evaluates, and optimizes the entire production process in a computer virtual environment based on relevant data throughout the entire product lifecycle, and further extends to the entire product lifecycle. SiE Information proposed that manufacturing enterprises have entered the stage of 3.0 innovation exploration after experiencing the application of 1.0 chimney system to 2.0 flat desktop integrated application in the past. The digital transformation of enterprise strategy is to upgrade from all aspects such as logistics, supply chain, manufacturing, trading, products, services, etc. Electric motor enterprises have the characteristics of both mass production and customer customization, large demand differences, multiple changes, complex product structure and process, need to manage material expiration dates, short production cycles, complex management, multiple suppliers, high supporting requirements, and high difficulty in timely material supply. How to reasonably organize the design and production of various, complex, and customized products within the specified time frame, deliver high-quality products to meet customer needs, while ensuring one's own profits and achieving market value is a problem that all motor companies need to consider.

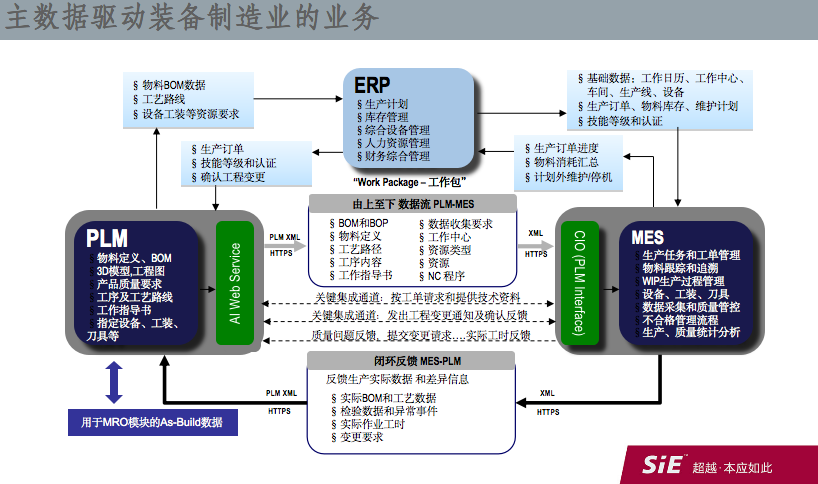

Based on 15 years of exploration and accumulation in the digital transformation of service enterprises, SiE Information believes that the construction of a digital chemical factory should first build a business driven by master data in the equipment manufacturing industry. Because the digital factory solution is a highly integrated automation and information integrated solution that unifies the management of various equipment at the bottom of factory automation, and achieves data connection and interaction with information systems such as PLM and ERP at the top through intelligent devices at the middle layer, achieving automation and intelligence from product design to production. By constructing a series of management applications such as supply chain planning system, workshop operation plan, and external supply chain planning system, we achieve high efficiency and humanization of operational management.

As one of the most promising leading enterprises in the field of digital services for domestic enterprises, SiE Information focuses on the application of new generation information technology, industrial internet, intelligent manufacturing, digital transformation technology, and business models. The manufacturing operation management system SMOM independently developed by SiE Information is a set of digital and intelligent factory design concepts, providing enterprises with an information solution that integrates supplier collaboration portal, internal planning collaboration platform, production and manufacturing execution management platform, automated data collection, equipment integration and monitoring management, full process product information traceability, and intelligent operation management. It is an internal engineering and planning platform for enterprises, The guarantee system for the business system of logistics, production, and quality departments. By building a digital operation management platform centered on SMOM, we aim to bridge the information silos between business units such as customer needs, procurement support, production and manufacturing services, order delivery, and work units, and establish a standardized management system for enterprises with multiple product lines and business organizations. By integrating cross business processes/departments/regions/enterprises through information platforms, end-to-end integration and collaborative manufacturing can be achieved, enhancing the operational capabilities of the value chain.

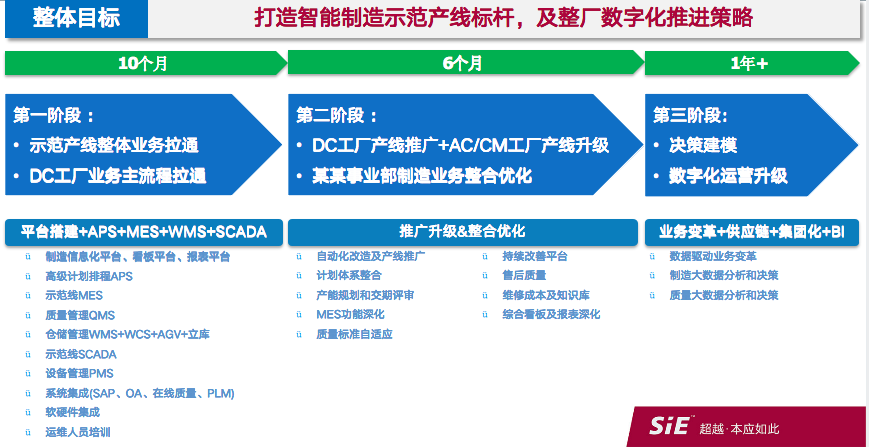

The digital advancement of enterprises is divided into three steps

At the meeting, SiE Information also shared the promotion strategy of building a benchmark for intelligent manufacturing demonstration production line and digitizing the entire factory. SiE Information divides the entire digital factory construction into three stages. The first stage mainly involves intensive management, connecting the overall business of the demonstration production line with the mainstream process of the DC factory business, and building a platform+APS+MES+WMS+SCADA. This stage mainly involves building a basic framework and connecting the entire process; The second stage is to achieve refined management, promote the DC factory production line and upgrade the AC/CM factory production line, and integrate and optimize the manufacturing business of relevant business units; The third stage is for modeling digital management decisions and upgrading digital operations.

Over the past 15 years, SiE Information has served over 1000 well-known industry clients in fields such as enterprise digital transformation, including Midea, Huawei, Alibaba, Ping An, CIMC, China Unicom, Panasonic, and TCL. It has accumulated rich experience in exploring and practicing Digital Factory 2.0 by integrating fully integrated automation, manufacturing operation management, and product lifecycle management, Assist enterprises in organizing clear intelligent manufacturing blueprints and step-by-step implementation steps, so that every stage of building a digital factory can see the improvement of target benefits and achieve intelligent manufacturing upgrading.